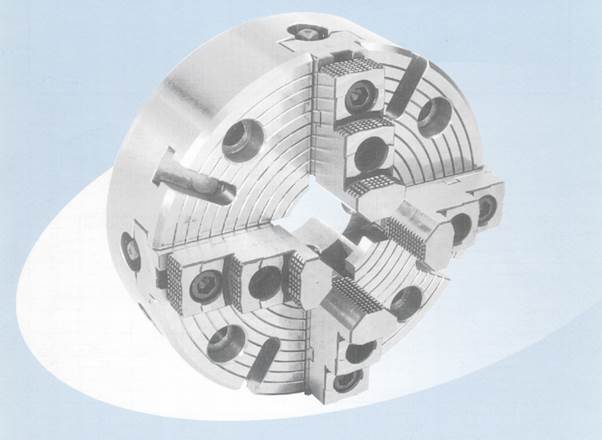

The MTPL four-jaw chuck boasts several key attributes that set it apart from other four-jaw independent chucks on the market.

To begin with, the chuck body is meticulously crafted from forged medium-carbon steel, a material that undergoes a process of hardening and tempering to ensure both longevity and structural integrity. The base jaw slots within the body are precision-ground to exacting tolerances, enabling a great sliding fit. This precision engineering guarantees a play-free operation, remarkable load-bearing capability, and optimal wear resistance.

What truly distinguishes MTPL’s independent four-jaw chuck system is the provision of separate jaws and reversible hard jaws. This design feature allows the flexibility to employ specialised hard jaws tailored to specific components.

The hard jaws are affixed to the base jaws via a tongue-and-tenon arrangement, enabling them to securely grip a wide range of components, whether on their outer diameter or inner diameter.

Furthermore, the base jaws are meticulously produced from alloy steel and subjected to case hardening. They are designed to be deeper and wider, thereby providing substantial bearing areas with reduced unit bearing pressure. This design enhancement significantly extends the chuck’s operational lifespan.

Another notable feature is the incorporation of square threads on the screws and the undersides of the base jaws. These threads engage more extensively, resulting in efficient transmission and conversion of applied torque. The screws themselves undergo heat treatment to prevent breakage, addressing a common concern in commercial-quality chucks.

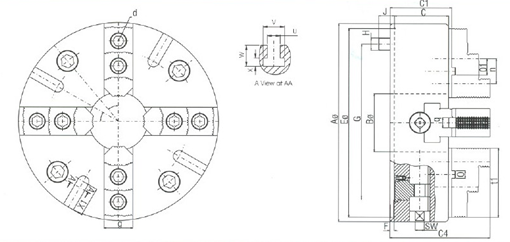

| Model | 34-06 | 34-07 | 34-08 | 34-09 | 34-10 | 34-11 | 34-12 | 34-13 | 34-14 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Size | 250 | 315 | 400 | 500* | 630* | 800* | 900* | 1000* | 1200* | |

| Aø | 250 | 315 | 400 | 500 | 630 | 800 | 900 | 1000 | 1200 | |

| Bø | 68 | 92 | 130 | 170 | 245 | 385 | 380 | 380 | 380 | |

| C | 83 | 86 | 98 | 98 | 108 | 140 | 140 | 140 | 140 | |

| C1 | 95 | 98 | 110.5 | 110.5 | 119 | 155 | 155 | 155 | 145 | |

| C4 | 146 | 158 | 175 | 185.5 | 199 | 265 | 280 | 280.5 | 280 | |

| Eø H8 | 235 | 300 | 380 | 460 | 580 | 710 | 710 | 710 | 710 | |

| F | 7 | 7 | 7 | 7 | 6 | 10 | 10 | 10 | 10 | |

| G PCD | 200 | 250 | 315 | 400 | 520 | 660 | 660 | 660 | 660 | |

| H | 4 x M16 | 4 x M20 | 4 x M 20 | 4 x M24 | 4 x M24 | S x M24 | 8 x M24 | 8x M24 | 8 x M24 | |

| J | 24.5 | 25 | 38.5 | 35.5 | 38 | 35 | 35 | 35 | 35 | |

| SW | 14 | 14 | 17 | 17 | 17 | 24 | 24 | 24 | 24 | |

| U H12 | 14 | 18 | 18 | 22 | 22 | 22 | 22 | 22 | 22 | |

| V | 23 | 30 | 30 | 37 | 37 | 40 | 40 | 40 | 40 | |

| W | 25 | 30 | 30 | 38 | 38 | 38 | 38 | 38 | 38 | |

| X | 9 | 12 | 12 | 16 | 16 | 16 | 16 | 16 | 16 | |

| X1 | 42 | 47 | 60 | 64 | 160 | 127 | 180 | 230 | 330 | |

| d | 8 x M14 | 8 x M16 | S x M16 | 8 x M20 | 8 x M20 | 12 x M20 | 12 x M20 | 12 x M20 | 12 x M20 | |

| g | 38 | 45 | 50 | 50 | 60 | 60 | 60 | 60 | 60 | |

| n | 35 | 40 | 50 | 60 | 60 | 170 | 200 | 200 | 200 | |

| o g6 | 12 | 12 | 12 | 12 | 12 | 22 | 22 | 22 | 22 | |

| o1 | 23.5 | 26 | 31 | 36 | 36 | 96 | 111 | 111 | 111 | |

| q H7 | 16 | 16 | 16 | 16 | 16 | 22 | 22 | 22 | 22 | |

| t1 | 93 | 110 | 130 | 160 | 195 | 255 | 300 | 300 | 300 | |

| Outer Clamping | Max | 250 | 315 | 400 | 500 | 630 | 800 | 900 | 1000 | 1200 |

| Min | 20 | 35 | 40 | 58 | 78 | 130 | 130 | 130 | 130 | |

| Inner Clamping | Max | 250 | 315 | 400 | 500 | 630 | 800 | 900 | 1000 | 1200 |

| Min | 68 | 84 | 106 | 152 | 232 | 320 | 340 | 340 | 340 | |

| RPM Max. | 2400 | 1900 | 1500 | 1200 | 1000 | 500 | 445 | 400 | 335 | |

| Approx weight (KG) | 33 | 55 | 90 | 138 | 241 | 425 | 600 | 840 | 1150 | |

Each chuck is supplied with – one set of reversible hard jaws, one number box spanner with tommy bar, one number allen wrench for jaw screws and one set of chuck clamping screws

* = Special sizes

Note : Minimum 2/3 engagement between screw and base jaw to be maintained during clamping.